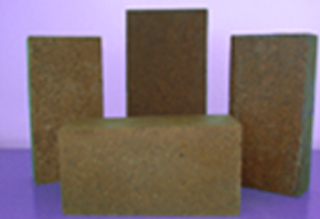

With the continuous development of technology, more and more new products appear on the market, and the things we will encounter are becoming more and more abundant. The price of magnesium bricks provides us with more choices. When we need to use one thing First of all, we need to understand what it is, what it is useful for, and whether it is good to use. Let us take a lightweight refractory brick as an example to talk about what it is and related knowledge.

What is a lightweight refractory brick? First understand from the definition of the name, refractory products with small density, light weight and low thermal conductivity are used for heat insulation. For example: clay insulation brick, high alumina poly light brick, mullai Stone insulation bricks, bleached pearl bricks, alumina hollow ball bricks, etc. are all lightweight refractory brick products.

The heat storage loss of industrial kiln masonry and the heat dissipation loss on the surface of the furnace body generally account for about 24 to 45% of the fuel consumption. Using light bricks with low thermal conductivity and small heat capacity as the structural material of the furnace body can save fuel consumption; meanwhile, Because the kiln can quickly heat up and cool down, it can improve the production efficiency of the equipment; it can also reduce the weight of the furnace body, simplify the kiln structure, improve product quality, reduce environmental temperature, and improve working conditions.

I. Definition of Lightweight Refractory Brick:

Generally refers to refractory bricks with a density of less than 1.3 × 103Kg / m3. Light weight means that the quality of this refractory brick is light.

Second, lightweight refractory bricks have the following characteristics:

1, small density, light weight, can reduce the weight of the furnace body and simplify the structure of the furnace;

2.High porosity, small thermal conductivity, good thermal insulation, can save fuel consumption and improve equipment production efficiency;

3, low mechanical strength, can not be used for load-bearing structures;

4.Poor abrasion resistance, it should not be used in areas that are in contact with the charge and have severe wear;

5.The porosity is large, and it can not be used in direct contact with slag and liquid metal parts.

Lightweight refractory bricks have light weight and heat insulation, but they are not high in strength and poor in abrasion resistance, and cannot be exposed to high temperature flames; in the weight of heavy refractory bricks, they have poor heat insulation capabilities, but they have high strength, high wear resistance, and high temperature resistance. For high-temperature equipment, according to the actual situation according to the needs, the combination of light refractory bricks and heavy refractory bricks according to the design scheme will achieve good results, and will increase the equipment life and use efficiency.

III. Production methods of lightweight refractory bricks

(1) Combustible additive method, that is, combustible materials such as wood chips or coke powder that are easily burned out in the match guessing. When the combustible materials are burned out during the firing process of the brick, many pores are left in the brick, which is commonly used. Approach;

(2) Foam method, that is, in the matching guess, participate in rosin soap and other foaming agents, and then burn into porous products;

(3) The chemical method, when participating in a substance in the match, a foaming chemical reaction can occur, such as dolomite or periclase plus gypsum, using dilute sulfuric acid as a foaming agent, a lot of CO2 occurs, and it is immediately cast and boring. After firing, the fire resistance of lightweight refractory bricks is similar to that of general refractory bricks of the same raw material, and the softening point of the load is slightly lower.

If light bricks are used at high temperatures for a long time, they will continue to sinter and shorten, forming cracks and even damage. Therefore, most light bricks have a problem with the application temperature. For example, the light clay bricks only need 1150 ℃, and the high can reach 1400 ℃. Light-weight high-alumina bricks do not exceed 1350 ° C, and light-weight silicon bricks can reach 1600 ° C. Since light-weight silicon bricks do not have the problem of high temperature shortening and are relatively stable in volume, they can be used to build interiors that directly touch the furnace gas. lining.

Lightweight refractory bricks have poor slag resistance, so lightweight refractory bricks cannot directly touch molten metal and slag. The mechanical strength and abrasion resistance of this type of brick are also slightly poor, and they are not suitable for high-speed airflow scouring and sensation. Large parts. Similar to the process of lightweight refractory bricks, in the matching of refractory concrete, participating in the appropriate foaming agent can be made into lightweight refractory concrete, the volume density is only one-half of that of clay bricks, and the thermal conductivity is the same as that of clay bricks. One-third. If vermiculite or ceramsite is used as aggregate, the density and thermal conductivity are lower.

Address: Steel Industrial Park, Laobian District Industrial Park, Yingkou City, Liaoning Province Consulting Hotline: +86-133-5230-7686 +86-153-0417-8351

Technical Support: Yingkou Zhongchuang Network Technology Co., Ltd. All rights reserved.

Copyright ? Yingkou Sensheng Tenai Co., Ltd. All rights reserved record number:Liao ICP No. 19013533-1 Specializing in,Welcome to inquire! Technical Support:Xiangyun platform service support:Yingkou Zhongchuang Network Technology Co., Ltd.